These days, I tried to mill a rounded edge profile of an aluminum electric motor lid, used as eye catcher for a bulky custom alteration of a professional parmesan plan.

the result

We only talk about the upper part, held by the two screws. The gravure shows the logo of the customer's company, and it is done with an ordinary v-cutter with 30000rpm an 300mm/min feed rate, cooled manually with wd40 -- but that's nothing special, the rounded edges should get your focus.

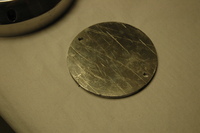

the start -- the raw aluminium

This is where I started: A laser cutted piece of aluminum, 100mm diameter. Yes, this is also possible to cut with my router, but I need a lot of cnc cut parts, and it is much more economic to give that work to someone else.

the tool

The edges are done with an ordinary cheap wood mill cutter, normally used on a wood router like the machine on the picture (picture found at http://de.wikipedia.org/wiki/Oberfräse)

The picture of the red milling cutter is the original tool, photographed after the work.

the cnc router

Although it is not build for metal chipping (like my 750kg Deckel FP1), in case of short axes and their stiff construction my machine is able to take some energy. I was surprised how easy it was to do. The mill was running 10000rpm, 300mm/min, 0.5mm deep/path with no cooling and it was so relaxed that I'm sure it is possible to raise the parameters. But my work piece is done now. :)

Wulf Coulmann

Berlin Germany

Fax +49-30-45.02.97.45

E-Mail: scripts at gpl.coulmann dot de

Inhaltlich Verantwortlicher gemäß

§ 6 MDStV: Wulf Coulmann

the tool

The edges are done with an ordinary cheap wood mill cutter, normally used on a wood router like the machine on the picture (picture found at http://de.wikipedia.org/wiki/Oberfräse)

The picture of the red milling cutter is the original tool, photographed after the work.

the cnc router

Although it is not build for metal chipping (like my 750kg Deckel FP1), in case of short axes and their stiff construction my machine is able to take some energy. I was surprised how easy it was to do. The mill was running 10000rpm, 300mm/min, 0.5mm deep/path with no cooling and it was so relaxed that I'm sure it is possible to raise the parameters. But my work piece is done now. :)

Wulf Coulmann

Berlin Germany

Fax +49-30-45.02.97.45

E-Mail: scripts at gpl.coulmann dot de

Inhaltlich Verantwortlicher gemäß

§ 6 MDStV: Wulf Coulmann

Wulf Coulmann

Berlin Germany

Fax +49-30-45.02.97.45

E-Mail: scripts at gpl.coulmann dot de

Inhaltlich Verantwortlicher gemäß

§ 6 MDStV: Wulf Coulmann